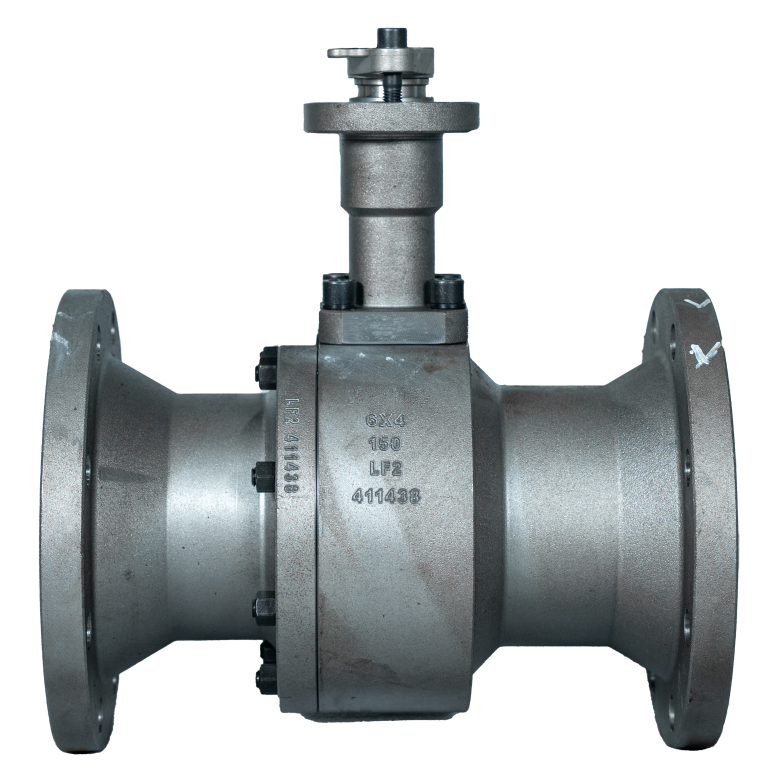

AsalAra Forged Steel Ball Valve

- Forged Steel Ball Valve

The AsalAra Forged Steel Ball Valve is engineered for high-pressure and high-temperature industrial applications requiring superior mechanical strength and sealing reliability. Forged body construction provides enhanced grain structure and uniformity, reducing the risk of porosity and structural failure compared to cast components.

Ideal for applications in power generation, petrochemical, refinery, and upstream oil & gas, Falcon forged ball valves ensure leak-tight performance, anti-blowout stem integrity, and long lifecycle operation. Available in floating or trunnion-mounted designs, they can be customized with a range of end connections and actuators to meet project-specific demands.

NPS (inch)

DN (mm)

½” – 4”

DN 15 – DN 100

Standard

Rating

ASME

Class 150 – 2500

API

Up to 10,000 psi (optional)

- Body / Bonnet: A105, A350 LF2 (low temp), F304, F316, F316L, F51 (Duplex), F55 (Super Duplex)

- Ball: SS316 / ENP-Coated Carbon Steel / Inconel

- Seats: PTFE, RPTFE, PEEK, Devlon, Metal-to-Metal (Stellite, Tungsten)

- Stem: SS316 / 17-4PH / Inconel

- Gasket / Seals: Graphite, PTFE, Viton, Low Emission Packing (ISO 15848)

- Socket Weld (SW) – ASME B16.11

- Threaded (NPT/BSPT) – ASME B1.20.1

- Butt Weld (BW) – ASME B16.25

- Flanged RF/RTJ – ASME B16.5

- Hub Connection – optional for offshore and skid packages

- ISO 5211 Mounting Pad for actuation

AsalAra Forge Series

Forged Body Isolation Ball Valves

Forged Body Design

Greater mechanical strength, durability, and structural integrity

Compact Footprint

Ideal for space-constrained installations and skid packages

Fire-Safe Design

Certified to API 607 / API 6FA standards

Anti-Blowout Stem

Ensures safety during overpressure scenarios

Wide Temperature Range

Suitable for cryogenic to high-temperature applications

Bubble-Tight Shutoff

Conforms to API 598 / ISO 5208 leakage standards

Fugitive Emission Options

Low-emission stem packing per ISO 15848 available

Actuator Compatibility

Ready for electric, pneumatic, or hydraulic actuators

High-pressure oil & gas pipeline manifolds

Skid-mounted process units

Power plant steam and condensate lines

Refinery critical isolation points

Chemical and petrochemical units

FPSO modules and offshore platforms

Cryogenic units (on request with special materials)

- Floating Ball or Trunnion Mounted

- • Fire-safe & anti-static grounding

- Double Isolation and Bleed (DIB) variants

- Top-Entry or Side-Entry Construction

- Trunnion-Mounted or Floating Ball Design

- Extended Stem for buried service

- Fully welded or split-body options

- API 6D / ISO 14313

- API 6FA, API 607 Fire Safe

- ASME B16.34, B16.5, B16.10

- PED 2014/68/EU

- NACE MR0175 / ISO 15156

- ISO 15848-1 (Low Emission – optional)

AsalAra’s Floating Ball Valves reflect global engineering excellence — delivering reliability, safety, and longevity. Whether for compact utility systems or high-pressure gas pipelines, Falcon offers unmatched sealing technology and lifecycle value.